Many condensing boilers are installed in homes that are fitted with conventional baseboard. Most homeowners who have these boilers installed are under the impression they’re getting more for their money. Unfortunately they’re not realizing the vast savings they were led to expect. Why? In short, because the boiler still needs to deliver 180˚ water to the baseboard in order to heat the house properly.

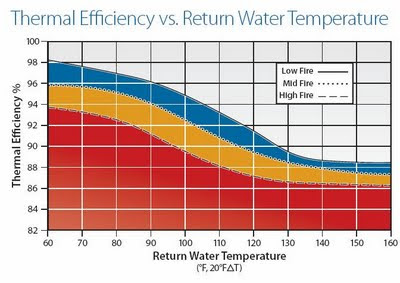

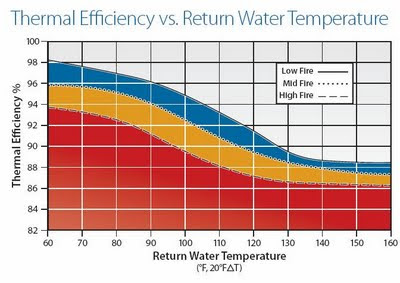

Modulating Condensing boilers achieve their highest efficiencies when delivering low temperature water and receiving low return water temperatures (see the chart below). The actual operating efficiency depends on the temperature of the return water stream: if it’s too warm then little condensation takes place and little extra energy is extracted. The lower the return water temp in relation to that of the products of combustion, the greater the heat transfer to the water and thus greater efficiency. There’s no doubt that mod-con boilers are much more efficient than conventional boilers, but by sticking with conventional baseboard, they’re not realizing their full potential by rarely operating in condensing mode as they were designed to do. To achieve the ultimate high efficiency system that allows the boiler to condense the majority of the time the installer needs to choose the ideal equipment for delivering heat using lower temperature water. This is where Smith’s Environmental comes in. Due to their unique designs, Smith’s products have the ability to deliver comparable BTUH’s to conventional equipment using 100˚- 120˚ F supply water.

A given length of Smith’s HE2 High Capacity Hybrid Heating Element can be used to replace the same length of regular baseboard and still deliver comparable BTU’s using much lower temperature water. For example; a 10’ length of conventional baseboard has the ability to deliver roughly 600 BTU’s per linear foot or 6,000 BTU’s total with 180˚ supply water at 4 GPM. A 10’ length of HE2 can deliver the same amount of BTU’s with only 120˚ supply water at 1 GPM* (*when installed with the two supplies in parallel). At a 20˚ ΔT, the 100˚ return water temperature will enable the boiler to operate in full condensing mode for much greater efficiency.

Geothermal heat pumps and solar-thermal collectors are designed to deliver lower temperature water making the proper choice of heating equipment that can deliver the necessary BTU’s even more critical. Don’t short-change your customers! Give them the highest efficiency system possible by utilizing high efficiency heating components by Smith’s Environmental Products when installing Mod Con boilers!

Learn more in our free catalog here.